Tencan Double Cone Mixer – Efficient and Energy-Saving Mixing for Lab & Industrial Use

Datos del producto:

| Lugar de origen: | Hunan, China |

| Nombre de la marca: | TENCAN |

| Certificación: | CE ISO |

| Número de modelo: | SZX-50L |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 JUEGO |

|---|---|

| Precio: | Negociable |

| Detalles de empaquetado: | caja de madera contrachapada |

| Tiempo de entrega: | Entre 20 y 30 días hábiles después de recibir el pago completo |

| Condiciones de pago: | T/T, Unión Occidental |

| Capacidad de la fuente: | 500 sistemas por mes |

|

Información detallada |

|||

| nombre de la máquina: | Mezclador de doble cono | Presupuesto: | 5-300L |

|---|---|---|---|

| Material: | Acero inoxidable 304 | Voltaje: | 220V o 380V |

| Embalaje: | caja de madera contrachapada | Aplicaciones: | mezcla de polvo |

| Lugar de origen: | Hunan, China | Certificado: | CE ISO |

| Resaltar: | Tencan double cone powder mixer,energy-saving lab mixing machine,industrial double cone blender |

||

Descripción de producto

TENCAN 5–300L Lab/Industrial Double Cone Mixer – High Efficiency & Low Energy Consumption

Overview

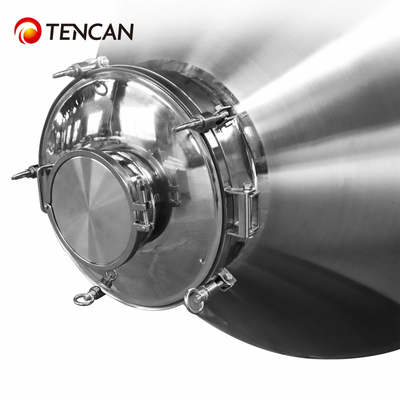

The TENCAN Double Cone Mixer is engineered for uniform blending of powders and granular materials. Its design supports applications across ceramics, magnetic materials, chemicals, metallurgy, pharmaceuticals, feed production, and related industries.

Construction options include polished stainless steel or liners made of wear-resistant materials such as corundum or polyurethane, depending on process requirements. The mixer is optimized for free-flowing powders and fine granular materials, delivering consistent results that meet international quality standards.

Key Features

-

High Mixing Uniformity: Ensures homogenous distribution of additives and micro-materials

-

Energy Efficient: Low power consumption compared to traditional mixers

-

User-Friendly Operation: Simple design reduces labor intensity

-

Versatile Material Handling: Capable of mixing fine powders, wet mixtures, and granular materials

-

Durable Construction: Stainless steel and optional wear-resistant liners for extended service life

-

Scalable Capacity: Available in laboratory (5 L) to industrial-scale (300 L) models

Applications

-

Ceramics: Alumina, zirconia, technical ceramics

-

Magnetic Materials: Ferrites, soft magnetic powders

-

Chemicals & Pharmaceuticals: Powders, granules, additives

-

Metallurgy: Alloy powders, metal composites

-

Feed & Food Industry: Nutrient blends, dry feed formulations

-

Other Industries: Micro-material blending, powder coating, specialty materials

![]()

Working Principle

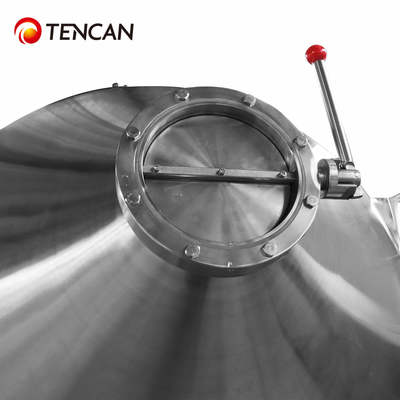

The Double Cone Mixer operates similarly to a V-type mixer. Materials are loaded into the double-cone-shaped container, which rotates at high speed, causing the contents to undergo continuous tumbling and impact. This motion ensures thorough and uniform mixing.

| Parameter | Specification |

|---|---|

| Product Name | Double Cone Powder Mixer |

| Brand | TENCAN |

| Model | 5–300L |

| Capacity | 5–300 L |

| Mixing Method | Dry / Wet |

| Mixer Body Material | Polished stainless steel or lined with corundum / PU |

| Suitable Materials | Free-flowing powders, granular materials, wet mixtures |

| Energy Consumption | Low (high energy efficiency) |

| Operation | Manual or motor-driven rotation |

| Applications | Ceramics, chemicals, magnetic materials, pharmaceuticals, feed, metallurgy |

| Features | Uniform mixing, low labor intensity, scalable capacity |

![]()

![]()